Transform Industrial Processes with Reactive Flow CFD Simulations

- VirtualCAE

- 12/06/2025

- Blog

- CAE, CFD, English

- 0 Comentários

Simulate thermal and chemical phenomena with precision to optimize designs, validate hypotheses, and ensure operational safety.

Industrial processes involving chemical reactions (such as combustion, oxidation, synthesis, or thermal treatments) are inherently complex and sensitive to change. Variables like temperature, flow velocity, reactant ratios, and system geometry can significantly impact efficiency, safety, and product quality. When fluids are in motion while chemical reactions take place, you’re dealing with a multifaceted challenge: mass, heat, and chemical species transport interacting simultaneously. Predicting this behavior through physical testing alone is limited, costly, and time-consuming.

That’s where CFD (Computational Fluid Dynamics) simulations with chemical modeling become a strategic tool for engineers and industrial managers. By virtually replicating real process conditions using accurate mathematical models, it’s possible to understand the system’s behavior in detail—even in regions where physical sensors can’t reach.

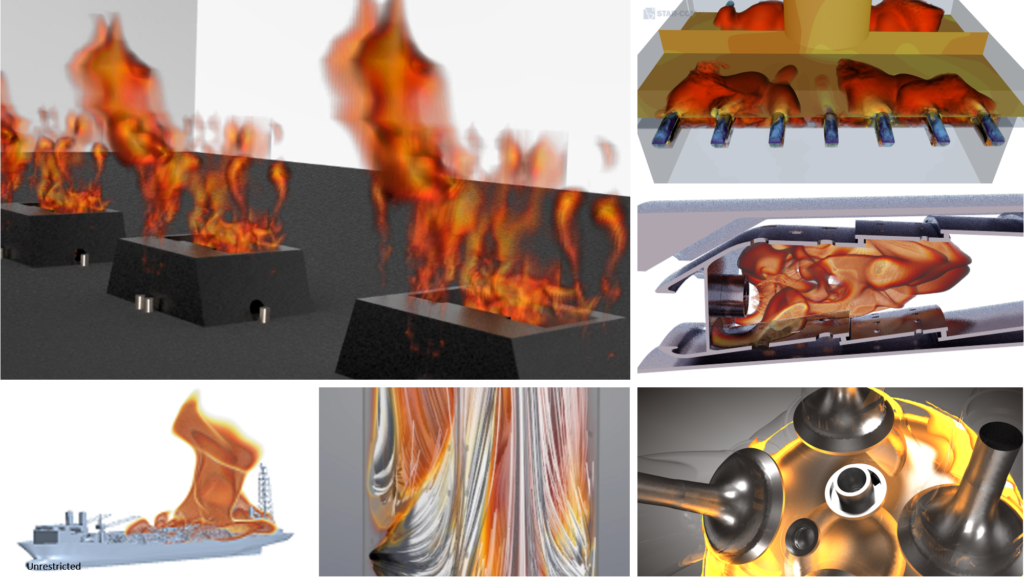

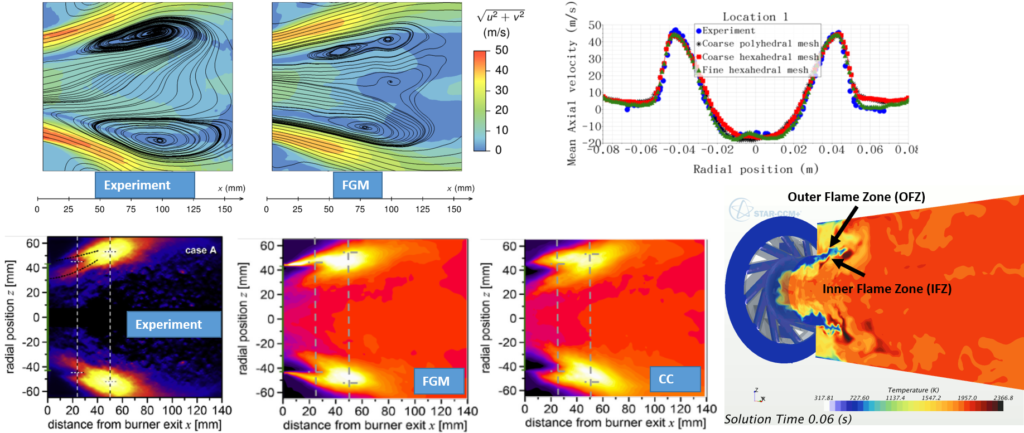

Starting from the equipment geometry and fluid properties, simulations build a three-dimensional model of the process. Equations governing heat, momentum, and species transport are solved in conjunction with chemical reactions. This enables engineers to visualize how mixtures behave, where reactions are most intense, what areas pose thermal risks, and where unwanted by products may form.

This approach has practical applications across various industries. In the energy sector, simulations can model fuel combustion in boilers or burners, revealing inefficiencies or excessive pollutant formation. In the chemical industry, reactor simulations help optimize geometry and operating conditions to improve yield and reduce waste. Environmental systems such as incinerators or catalytic converters benefit from predictive modeling to ensure emissions meet increasingly strict regulations.

Beyond technical improvements, simulations contribute directly to cost reduction. By identifying problems during the design phase, costly rework and operational changes can be avoided. Simulations also enable scenario testing safely and affordably, something that’s often impractical physically, bringing speed and confidence to the development process.

Another key benefit is process safety. In systems with ignition risks, pressure surges, or uncontrolled heat release, understanding flow-reactive behavior in advance allows for proper relief system design, material selection, and safe operating parameters. Engineering becomes proactive instead of reactive.

Reactive flow simulations must go beyond generating charts and visualizations—they must yield actionable insights. When interpreted correctly, simulation results become a solid foundation for decisions in design, operations, and process improvement. Transforming raw data into reliable technical knowledge makes CFD a strategic tool, not just for validating ideas but for driving clear, confident actions.

If your company deals with thermal or chemical processes where fluid dynamics and reactions play a critical role, now is the time to explore how CFD simulations can transform your outcomes. Understand your process in depth, detect hidden inefficiencies, and explore smarter, safer solutions, with accuracy and confidence.

Get in touch and find out more about the services and products offered by VirtualCAE. ✅